Suzuki GSX-R 1000 Service Manual: Engine bottom side assembly

Assemble the engine bottom side in the reverse order of disassembly. Pay attention to the following points:

| Note apply engine oil to each running and sliding part before reassembling. |

Breather oil return plate

When installing the breather oil return plate (1), apply thread lock to the bolts.

: Thread lock cement

: Thread lock cement

99000–32110 (thread

lock cement super “1322” or equivalent)

Oil seal / bearing

Install the oil seal and bearings. Refer to “transmission installation” in section 5b .

Water jacket plug

- Apply engine coolant to the o-rings of the water jacket plugs.

- Tighten each plug to the specified torque.

| Caution replace the o-rings with new ones. |

Tightening torque water jacket plug (a): 9.5 N·m (0.95 Kgf-m, 6.9 Lbfft)

Oil gallery plug

| Caution replace the gaskets with new ones. |

- Apply thread lock to the oil gallery plug (m10) and tighten it to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque oil gallery plug (m10) (a): 18 n·m (1.8 Kgf-m, 13.0 Lbf-ft)

- Apply thread lock to the oil gallery plug (m12) and tighten it to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque oil gallery plug (m12) (b): 15 n·m (1.5 Kgf-m, 11.0 Lbf-ft)

- Tighten the oil gallery plugs to the specified torque.

Tightening torque oil gallery plug (m26) (c): 11 n·m (1.1 Kgf-m, 8.0 Lbf-ft) oil gallery plug (m6) (d): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

Oil jet

Install the oil jet (1) (for transmission).

Crankshaft journal bearing

When fitting the crankshaft journal bearings to the upper and lower crankcases, be sure to fix the stopper part “a” first and press the other end.

| Caution do not touch the bearing surfaces with your hands. Grasp by the edge of the bearing shell. |

| Note inspect and select the crankshaft journal bearing if necessary. Refer to “crankshaft journal bearing inspection and selection” . |

Piston and conrod

- Apply a small quantity of molybdenum oil solution onto each piston pin.

M/o: molybdenum oil (molybdenum oil solution)

- Assemble the piston and conrod.

| Note when installing the pistons, the indent “a” on the piston head must be brought to the other side of id code “b” on the conrod big end. |

- Install the piston pin circlips (1).

| Caution use new piston pin circlips (1) to prevent circlip failure which will occur when it is bent. |

| Note end gap of the circlip “c” should not be aligned with the cutaway in the piston pin bore. |

- Apply a small quantity of molybdenum oil solution to the sliding surface of the pistons and cylinder walls.

M/o: molybdenum oil (molybdenum oil solution)

| Note be sure to install the pistons in the cylinders from which they were removed in disassembly, referring to the cylinder numbers, #1 through #4, scribed on the piston. |

- Install the pistons with conrods into the cylinders from topside using the special tool.

| Note when installing the pistons, the indent “d” of each piston head must be brought to the exhaust side. |

Special tool

(a): 09916–77310 (piston ring

(a): 09916–77310 (piston ring

compressor)

- Check that i.D. Code “e” on each conrod faces intake side.

| Caution be sure to clean the conrod big end. |

Piston cooling oil jet

- Fit new o-ring (1) to each piston cooling oil jet and apply engine oil to it.

| Caution use new o-ring to prevent oil pressure leakage. |

- Install each piston cooling oil jet.

| Note apply a small quantity of thread lock to the bolts and tighten them to the specified torque. |

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque piston cooling oil jet bolt (a): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

Crankshaft

- Apply molybdenum oil to each crank pin bearing surface and crankshaft journal bearing surface.

M/o: molybdenum oil (molybdenum oil solution)

- Position the no. 2 And no. 3 Conrod big ends on the same side, and the no. 1 And no. 4 Conrod big ends on the opposite side of no. 2 And no. 3.

- Set the crankshaft onto the conrods and upper crankcase.

- Apply molybdenum oil to each crank pin and bearing surface.

| Caution be sure to clean the conrod big end. |

M/o: molybdenum oil (molybdenum oil solution)

- When fitting the conrod cap, make sure that I.D.

Code “a” on each conrod faces intake side.

- Apply engine oil to the conrod cap bolts.

- Tighten the conrod cap bolt by using a 10 mm, 12 point socket wrench in the following two steps.

Tightening torque conrod cap bolt: 37 n·m (3.7 Kgf-m, 26.5 Lbf-ft) then turn in 1/6 (60°) turn

|

- Apply engine oil to the conrod big end side surfaces.

- Apply molybdenum oil to each crankshaft journal and bearing lightly.

M/o: molybdenum oil (molybdenum oil solution)

- Check the conrod movement for smooth turning.

- Insert the right and left thrust bearings with the oil grooves “b” facing towards the crankshaft web.

Note

|

Transmission

Install the transmission. Refer to “transmission installation” in section 5b .

Balancer shaft

- Apply a molybdenum oil solution to each balancer shaft journal and bearing lightly.

M/o: molybdenum oil (molybdenum oil solution)

- Set the balancer shaft so that its punch mark “a” is aligned with the index “b” on the crankshaft.

- Install the plug (1).

Crankcase

- Install the dowel pins and o-rings (1).

| Caution replace the o-rings with new ones. |

- Apply bond to the mating surface of the lower crankcase as follows.

Note

|

: Sealant 99000–31140 (suzuki

: Sealant 99000–31140 (suzuki

bond

no.1207B or equivalent)

- Tighten the crankshaft journal bolts (m9). Tighten each bolt a little at a time to equalize the pressure in the following two steps.

| Caution fit new gasket washers to the bolts “a” to prevent oil leakage. |

Tightening torque crankshaft journal bolt (m9): 18 n·m (1.8 Kgf-m, 13.0 Lbf-ft) then turn in 50°

- Tighten the crankcase bolts a little at a time to equalize the pressure.

- Install the cap (2).

Caution

|

Tightening torque crankcase bolt (m8) (initial): 15 n·m (1.5 Kgf-m, 11.0 Lbf-ft) crankcase bolt (m8) (final): 26 n·m (2.6 Kgf-m, 19.0 Lbf-ft) crankcase bolt (m6): 12 n·m (1.2 Kgf-m, 8.5 Lbf-ft)

- After the crankshaft journal bolts and crankcase bolts have been tightened, check that the crankshaft rotates smoothly.

- Also check that the driveshaft and countershaft rotate smoothly.

- Install the clutch push rod oil seal retainer (3).

- Apply thread lock to the bolts.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Oil pump

- Install the breather oil return pipe (1).

- Apply grease to new o-ring (2).

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

| Caution use a new o-ring to prevent oil leakage. |

- Install the o-ring and dowel pins.

- Install the oil pump (3) and tighten the oil pump bolts to the specified torque.

Tightening torque oil pump mounting bolt: 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

- Install the thrust washer (4) to the countershaft.

| Note the chamfer side “a” of thrust washer should face the crankcase side. |

- Install the oil pump drive sprocket (5) to the countershaft.

| Note teeth “b” on the sprocket must face the clutch side. |

- Pass the chain (6) between the oil pump drive and driven sprockets.

- Apply engine oil to the countershaft

- Apply engine oil to the bearing (7) and spacer (8) and install them into the sprocket.

Oil strainer / oil pressure regulator

- Apply grease to new o-ring (1).

| Caution use a new o-ring to prevent oil leakage. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Install the oil strainer (2).

- Apply grease to new o-ring (3).

| Caution use a new o-ring to prevent oil leakage. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Push in the oil pressure regulator (4) to the oil pump as shown.

Oil pan

- Install new gasket.

| Caution use new gasket to prevent oil leakage. |

- Install the oil pan (1) and plate (2).

- Apply thread lock to the plate bolts “a”.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

- Tighten the oil pan bolts and plate bolts diagonally to the specified torque.

Tightening torque oil pan bolt: 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

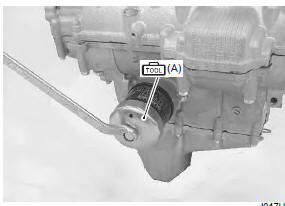

Oil filter

Install the oil filter with the special tool. Refer to “engine oil and filter replacement” in section 0b .

Special tool

(a): 09915–40610 (oil filter wrench)

(a): 09915–40610 (oil filter wrench)

Oil pressure switch

- Apply bond to the thread part of oil pressure switch and tighten oil pressure switch to the specified torque.

| Note be careful not to apply bond to the hole of thread end. |

: Sealant 99000–31140 (suzuki

: Sealant 99000–31140 (suzuki

bond

no.1207B or equivalent)

Tightening torque oil pressure switch: 14 n·m (1.4 Kgf-m, 10.0 Lbf-ft)

- Route the oil pressure switch lead wire properly and tighten the screw to the specified torque. Refer to “wiring harness routing diagram” in section 9a .

Gear position switch

- Apply grease to the o-ring.

| Caution replace the o-ring with a new one. |

| Note insert the gear position switch pin “a” into the gearshift cam hole “b”. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Tighten the gear position switch mounting bolts to the specified torque.

Tightening torque gear position switch mounting bolt (a): 6.5 N·m ( 0.65 Kgf-m, 4.7 Lbf-ft)

Water pump

- Apply grease to new o-ring (1).

| Caution use the new o-ring to prevent oil leakage. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Install the water pump assembly with the slot of the pump shaft end “a” securely engaged with the flat “b” of the oil pump shaft.

- Tighten the water pump mounting bolts (2) to the specified torque.

Tightening torque water pump mounting bolt (a): 10 n·m (1.0 Kgfm, 7.0 Lbf-ft)

- Apply engine coolant to the o-ring.

| Caution replace the o-ring with a new one. |

- Tighten the water inlet connector mounting bolts.

Generator

Install the generator rotor and cover (1). Refer to “generator removal and installation” in section 1j .

Cam chain / cam chain tensioner / cam chain guide no. 1

- Install the cam chain drive sprocket (1) to the crankshaft.

| Note when installing the cam chain drive sprocket, align the wide spline teeth of the sprocket and crankshaft. |

- Install the cam chain (2).

- Insert the cam chain tensioner and tighten the cam chain tensioner bolt (3) to the specified torque.

Tightening torque cam chain tensioner bolt (a): 23 n·m (2.3 Kgf-m, 16.5 Lbf-ft)

- Insert the cam chain guide no. 1 While pulling the chain upward.

- Tighten the cam chain guide no. 1 Bolt (4) to the specified torque.

Tightening torque cam chain guide no. 1 Bolt (b): 23 n·m (2.3 Kgfm, 16.5 Lbf-ft)

- Install the washer (5).

Starter clutch / starter torque limiter

Install the starter clutch (1) and starter torque limiter (2) component parts. Refer to “starter clutch removal and installation” in section 1i and “starter torque limiter removal and installation” in section 1i .

Gearshift system

Install the gearshift cam plate (1) and gearshift shaft (2).

Refer to “gearshift shaft / gearshift cam plate removal and installation” in section 5b .

Clutch

Install the clutch component parts (1). Refer to “clutch installation” in section 5c .

Starter motor

Install the starter motor (1). Refer to “starter motor removal and installation” in section 1i .

Crankcase breather (pcv) cover

- Apply bond to the hatching part of crankcase breather (pcv) cover.

: Sealant 99000–31140 (suzuki

: Sealant 99000–31140 (suzuki

bond

no.1207B or equivalent)

- Fit the clamp to the bolt “a”. Refer to “wiring harness routing diagram” in section 9a .

- Tighten the crankcase breather (pcv) cover bolts.

Engine top side

Assemble the engine top side. Refer to “engine top side disassembly” .

Engine bottom side disassembly

Engine bottom side disassembly

Note

the crankcase must be separated to service

the crankshaft and conrod.

Remove the engine assembly from the frame. Refer to “engine assembly

removal” .

Remove the e ...

Cylinder inspection

Cylinder inspection

Refer to “engine top side disassembly” .

Refer to “engine top side assembly” .

Cylinder distortion

Check the gasket surface of the cylinder for distortion.

Use a straightedge and thickness gau ...

Other materials:

DTC “c31” (p0705): gp switch circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

No gear position switch voltage

Gp switch voltage is not within the following range.

Gp switch voltage > 0.6 V

Gp switch circuit open or short.

Gp switch malfunction.

...

Water pump construction

Impeller

Mechanical seal

Oil seal

O-ring

O-ring

8

N·m (0.8 Kgf-m, 6.0 Lbf-ft)

10 N·m

(1.0 Kgf-m, 7.0 Lbf-ft)

Apply grease.

Apply engine coolant.

Apply molybdenum oil

solution.

Do not reuse.

...

Throttle valve synchronization

Check and adjust the throttle valve synchronization

among four cylinders.

Start the engine and run it in idling condition

for

warming up.

Stop the warmed-up engine.

Lift and support the fuel tank. Refer to “fuel

tank

removal and installation” in section 1g (page ...