Suzuki GSX-R 1000 Service Manual: Engine sprocket removal and installation

Removal

- Remove the gearshift link arm (1) from the gearshift shaft.

| Note mark the gearshift shaft head at which the gearshift link arm slit set for correct reinstallation. |

- Remove the speed sensor (2).

- Remove the engine sprocket cover (3).

- Support the motorcycle with a jack or wooden block.

- Loosen the rear axle nut (4) and left and right chain adjuster lock-nuts (5).

- Loosen the chain adjusters (6) to provide additional chain slack.

- Remove the speed sensor rotor (7) by removing its bolt while depressing the rear brake pedal.

- Remove the engine sprocket nut (8) while depressing the rear brake pedal.

- Remove the washer (9).

- Remove the engine sprocket (10).

Installation

Install the engine sprocket in the reverse order of removal. Pay attention to the following points:

- apply thread lock to the driveshaft.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

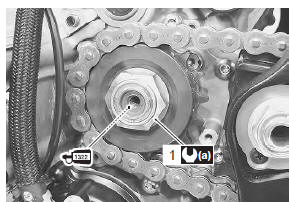

- Tighten the engine sprocket nut (1) to the specified torque.

Tightening torque engine sprocket nut (a): 145 n·m (14.5 Kgf-m, 105.0 Lbf-ft)

- Tighten the speed sensor rotor bolt (2) to the specified torque.

Tightening torque speed sensor rotor bolt (b): 28 n·m (2.8 Kgf-m, 20.0 Lbf-ft)

- Before installing the engine sprocket cover, apply a small quantity of grease to the clutch push rod.

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Install the engine sprocket cover (3).

- Tighten the speed sensor mounting bolt (4) to the specified torque.

Tightening torque speed sensor mounting bolt (c): 6.5 N·m (0.65 Kgf-m, 4.5 Lbf-ft)

- Fit the gearshift link arm to the gearshift shaft so that the gearshift lever is located at height “a” below the footrest.

Gearshift lever height “a” standard: 65 – 75 mm (2.6 – 3.0 In)

- Adjust the drive chain slack. Refer to “drive chain inspection and adjustment” in section 0b (page 0b- 14).

Drive chain related components

Drive chain related components

Drive chain

Engine sprocket

Rear sprocket

Dust seal

Bearing

Retainer

Sprocket mounting drum

Wheel damper

145 N·m (14.5 Kgf-m,

105.0 Lbf-ft ...

Rear sprocket / rear sprocket mounting drum removal and installation

Rear sprocket / rear sprocket mounting drum removal and installation

Removal

Remove the rear wheel assembly. Refer to “rear wheel assembly removal

and installation” in section 2d .

Loosen the rear sprocket nuts.

Draw out the rear sprocket mountin ...

Other materials:

Batiery

The battery is located under the

front seat. Remove the front seat

by referring to the seat lock

and helmet holders section.

This battery is sealed type

and requires no maintenance.

Have your dealer check the battery's

state of charge periodically.

The standard charging rate is

1.2A x ...

Battery current leakage inspection

Inspect the battery current leakage in the following

procedures:

turn the ignition switch off.

Remove the front seat. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Disconnect the battery (–) lead wire.

Measure the current betwee ...

Using the testers

Incorrectly connecting the (+) and (.) Probes may

cause the inside of the tester to be burned.

If the voltage and current are not known, make

measurements using the highest range.

When measuring the resistance with the multi-circuit

tester (1), ∞ will be shown as 10.00 ...